Mechanical Engineering

Mechanical Engineering

BNG, as a provider of highly customer-centric consulting and mechanical engineering services, offers a range of outsourced solutions tailored to meet the specific needs of companies across diverse industries. Our pragmatic problem-solving approach, proven offshore delivery model, and global presence, ensuring close proximity to our clients, make us the preferred engineering services partner for businesses worldwide. Whether it’s designing new products or tackling intricate engineering challenges, our multi-disciplinary team collaborates closely with you to engineer solutions for a wide spectrum of business requirements. With a commitment to high quality and timely delivery, we provide a seamless one-stop experience for all your mechanical engineering needs.

Product Design & Development

BNG has been successfully operating Product Development relationships with several global companies by enabling them to meet their Product Development objectives and Engineering activities.

Our aim is to transfigure your ideas to reality. Our engineering team ensures that proper analysis is carried out during project input gathering and arrive at appropriate project estimates.

Our product development team has developed the products for our customers that involve design study, detail engineering, prototyping and testing. The other areas where customers can rely on our team are:

- Concept design

- DFA (Design for Assembly) / DFM (Design for manufacturing)

- Detailed engineering design

- Engineering change management

- Reverse engineering/ Re-engineering

- Data conversion / migration

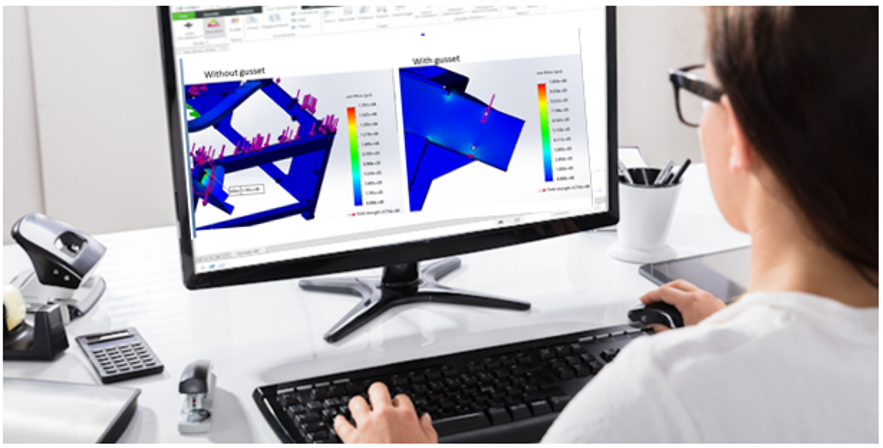

Computer Aided Engineering (CAE) Service

Our Engineering teams act as an extension of our Customers’ teams – responsible for delivering results on time and every time. We extend the capabilities of your engineering teams through unmatched global delivery excellence.

Finite Element Analysis is executed to validate the designs that are developed with a vision. We collaborate with design engineers to evaluate product design right from early design stages and minimize prototyping trials.

Our FEA specialists provide key insights on the product behavior and constraints that lead to possible pre-mature failure. Additionally, we deliver design optimization solutions for existing products and help reduce resource utilization while keeping product designs efficient and work on below areas of CAE activities.

- CAE / CFD modeling

- Static, Linear, Non-linear, Non-linear contact

- Dynamic, Buckling, Fatigue, Thermal Analysis

- Crash, Impact, Safety analysis

- CFD (Computational Fluid Dynamics)

- Design Optimization (Size, Shape & Topology)

- Multi body dynamic analysis

- Durability analysis

- Thermal and flow simulation

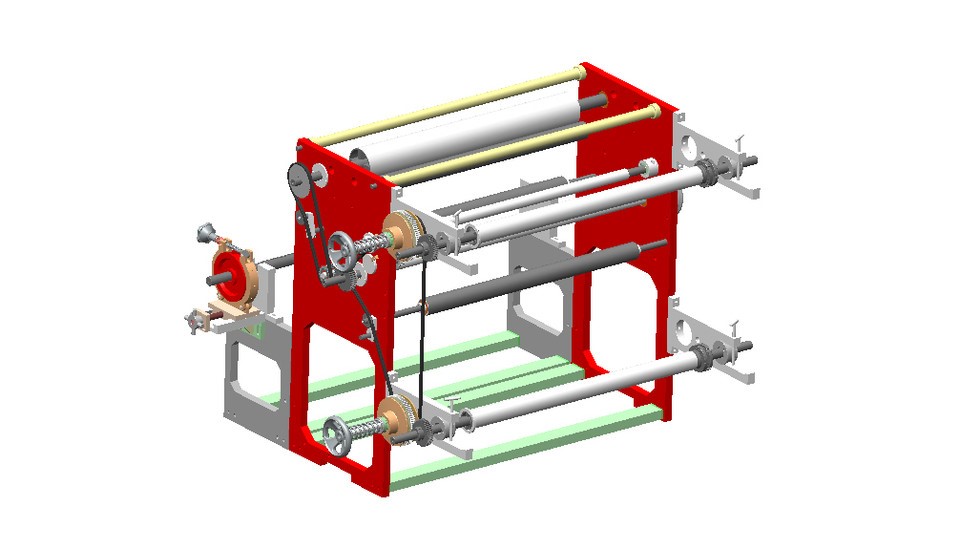

Special Purpose Machine Design

BNG strives to offer the best services in custom design machinery completed with the best effective solutions required for today’s market need. Our technical solutions cover a wide range of industrial or non-industrial branches. Our engineering team is capable to accomplish design for, basically, everything starting from individual pieces of equipment to larger machines and complex systems used in different sectors: industrial, medical, food and beverage, etc.

BNG is capable of developing product development relationships with prior experience of providing solutions for filling systems, wrapping systems, waste recovery systems and semi conductor equipment’s.

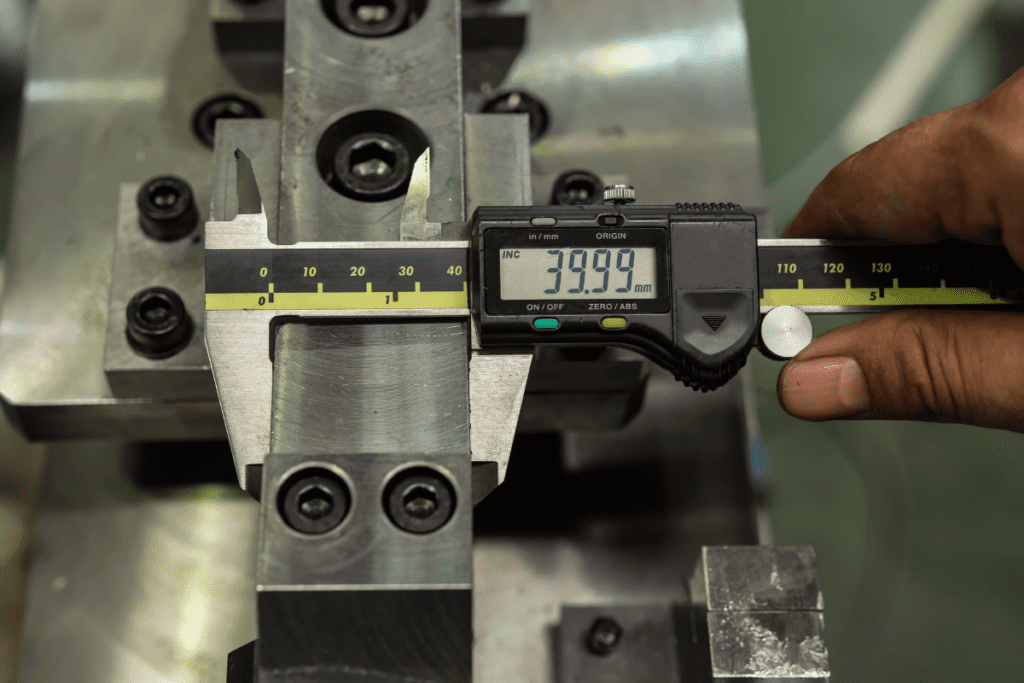

Jigs & Fixture Design

Our engineers have been complementing the design process by supporting our NPD projects with design and development of hydraulic, pneumatic and manual jigs and fixtures.

A jig is a specialized tool used to hold, support, and guide a workpiece during machining, assembly, or other industrial processes. It ensures precise positioning and alignment of the workpiece, enabling accurate and repeatable operations.

Fixtures are similar to jigs but serve a slightly different purpose. A fixture is a device that holds and locates a workpiece in a specific orientation during machining or assembly. Unlike jigs, which guide the tool or machine, fixtures primarily guide the workpiece.

- 2D/3D visualization of mechanical parts

- Welding and machining fixtures

- Assembly fixtures

- Compliance with industry/company specific standards

- Checking fixtures and check gauges

- Creation of 2D drawings

- Woodworking jigs and framing jigs

- Open or closed jig

- Hydraulic and pneumatic fixtures

- Process sheet preparation

- Testing fixtures

- Quality check

Sheet Metal Design / Fabrication

We have always delivered high-quality robust sheet metal designs that are compliant with the international standards. We have provided quality services to businesses across various industry sectors such as automobile, aerospace, electronics, power, transport, and telecom. Some of the key sheet metal product design services are listed here:

- 3D CAD Models

- 2D Engineering Drawings

- Bill of Materials (BOM)

- Assembly Instructions

- Tolerance Analysis

- Material Specifications

- Surface Finish and Coating Recommendations

- Functional Testing

- Performance Analysis

- Documentation

- Reverse Engineering Process Flowchart

- Simulation Models

- Finite Element Analysis (FEA) Results

- Stress and Strain Reports

- Design Validation Reports

- Material Selection and Analysis

Reverse Engineering

Component to CAD

We have developed various prototypes from the given physical samples to CAD models with new designs. These components range from a simple valve to hydraulic cylinders

Virtual Prototyping / Virtual Reality Model

Using this process products and environments are created through computer generated modeling techniques. These are rendered to simulate photographic images of a product or component in its own environment. 3D models of photo-realistic quality can supplant actual photographs of real objects and scenes, and in some cases these images are all that’s required to make a professional judgment about a new product.

CAD Data Migration Services

Data migration is always a big and challenging task. We have capabilities to handle large volumes of data from one software to other. Our engineers can create drawings, arrange and archive the data for easy retrieval. Before the beginning of any project, we gather customer preference details such as part assembly, folder structures for data storage, file naming, and font styles.

2D To 3D Conversion (Legacy Conversion)

BNG offers a complete range of highly accurate and high-quality 2D to 3D legacy data conversion services. Our engineers handle complete conversion projects with expertise using advanced tools and software. Our quality check criteria at every stage of the project ensures that our clients will receive accurate and error-free files within scheduled time frames committed.

Our team has the capability to support on the following migration types

- Legacy Data Migration

- CAD to CAD

- 2D to 3D

- 3D to 2D

- Tiff/PDF/Scanned Images to 3D

- Surface Modeling to Solid Modeling

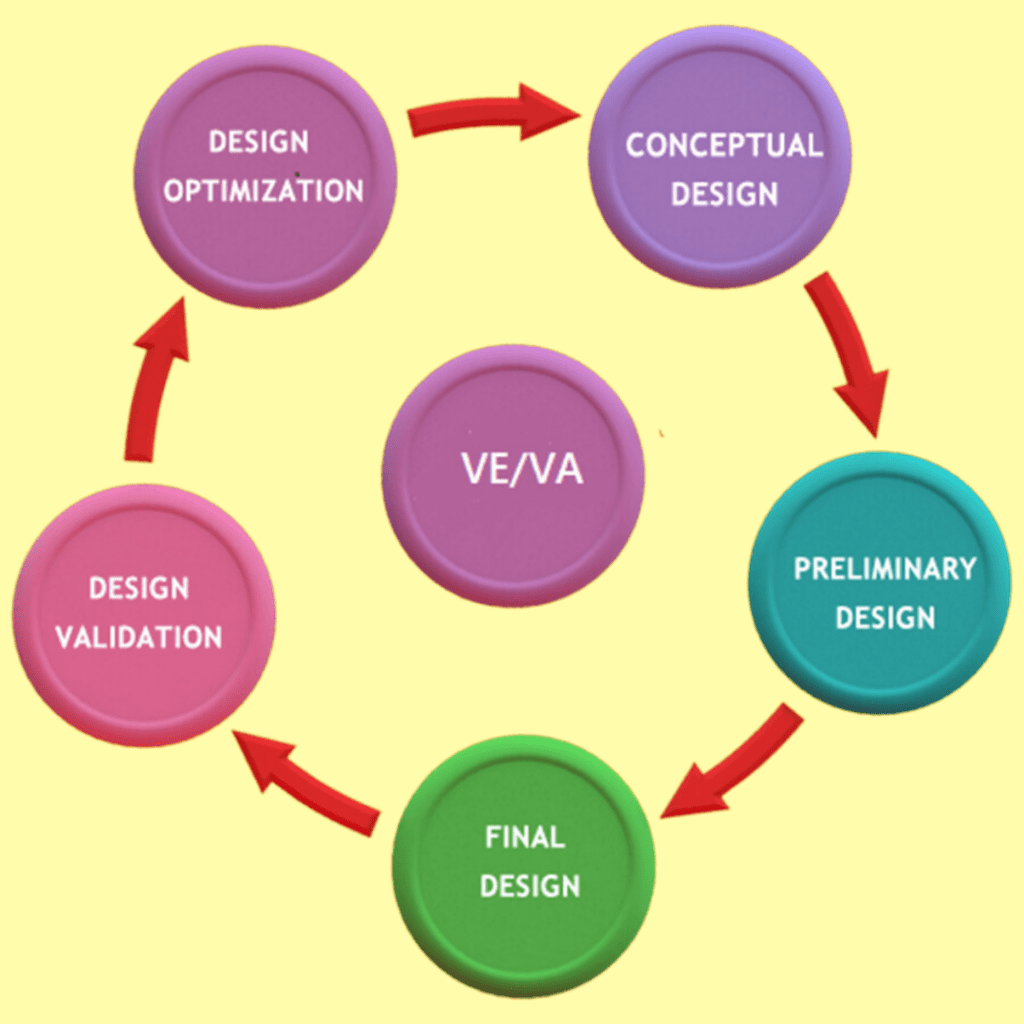

Value Analysis & Value Engineering (VA/VE)

Our engineers implement the VA/VE approach to deliver better (Return on Investment) ROI for our clients. We ensure the VE-VA team comes up with cost effective ideas. The simple yet effective process followed by BNG team to deliver Value Engineering design Services helps in identifying various design constraints facilitating a better understanding of design variables, manufacturing constraints and determines areas that can be improved considerably without compromising on the functionality.

Following are some of the services under VE-VA .

- Design optimization

- Warranty cost reduction

- Teardown and Benchmarking

- Product localization

- Should costing and sourcing support